+44 (0) 1924 452123

sales@taylor-studwelding.com

Stud Welding is a technique used to affix as a fastener onto a single side of a metal component. There are various Stud Welding processes to complete the fastening action. This article explores the differences between the three main stud welding techniques including capacitor discharge, drawn arc and short cycle stud welding to help you to identify which method is most suitable in your specific circumstances.

Selecting The Best Process

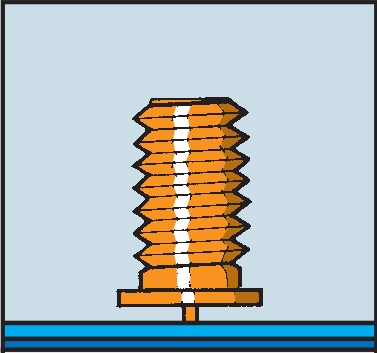

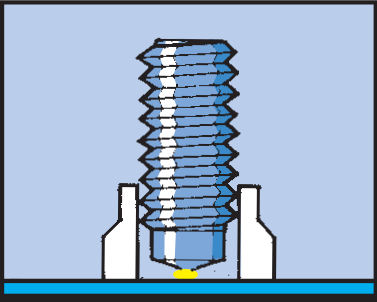

The Capacitor Discharge ‘CD’ Process

The Capacitors are charged to a pre-set voltage to suit the diameter to be welded. The stud pip is placed into contact with the sheet.

Upon triggering, the stored energy is discharged as a high current pulse, melting the pip and producing an arc.

Return spring pressure forges the stud into the molten surface area on the sheet to give complete fusion across the flange.

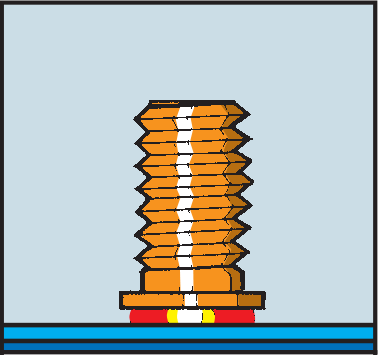

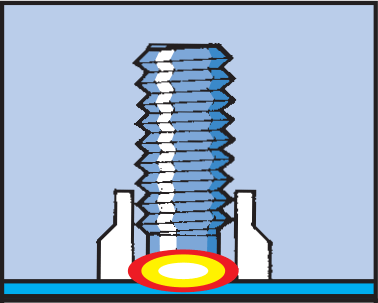

The Drawn Arc ‘DA’ Process

Current and weld time is pre-set to suit the diameter to be welded. The stud is then placed on the plate.

Upon triggering, a pilot arc occurs as the stud lifts to a pre-set height.

The main arc then melts the weld end of the stud and creates a molten pool in the plate.

Return spring pressure forges the stud into the molten pool. The ferrule contains the molten metal and shapes the fillet.

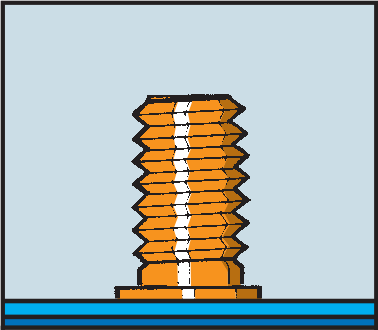

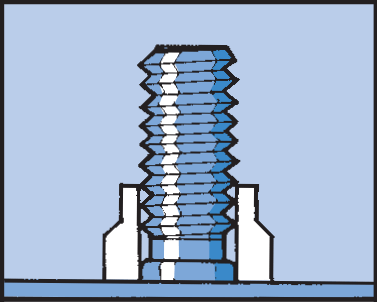

The Short Cycle ‘SC’ Process

The process is the same as for Drawn Arc ‘DA’ but operates over a much shorter time period – up to 100 milliseconds. Ceramic arc shields (ferrules) are not required with this process but shrouding with gas can improve weld fillet formation especially when welding Stainless Steel studs. Capacitor Discharge studs may be used.

Process | Stud/Material/ Power | Advantages |

Capacitor Discharge “CD” Designed specifically for thin gauge materials where reverse marking must be minimal. Sheet surface should be clean and flat. Stud has a weld pip. | Stud Diameter 1mm-M10 Material Thickness 0.7mm and above Power Requirements Single Phase 240/110 Volt | Low cost equipment, low cost studs, fast to load and weld, easy to jig and automate, small light equipment, no ferrules or shrouding gas required, good weld results with aluminium or brass in addition to mild and stainless steel. Weld is clean and requires no finishing. |

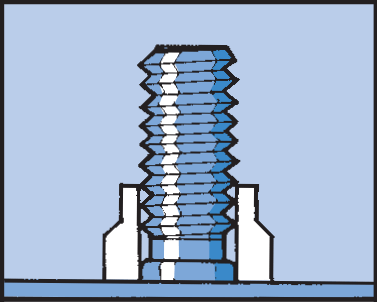

Drawn Arc “DA” Very strong penetrative welds are achieved with this process. Ferrules required to contain and shape molten metal. Weld end of stud is fluxed. | Stud Diameter 3mm to 30mm Material Thickness 2mm & above Power Requirements Three Phase 415 Volt | Burns through parent material laminations, tolerates surface curvature and imperfections e.g. light rust, scale, grease and some coatings. Gives neat and controlled weld fillet. The only method of Studwelding large diameters. This process also lends itself to multi-gun applications. |

Stud Diameter M3 to M8 Material Thickness 1.5mm & above Power Requirements Three Phase 415 Volt | This process is more tolerant than CD of uneven or dirty surfaces. Can be easily automated and can utilise low cost “CD” studs. Ferrules are not required however shrouding gas improves weld spatter. |

Suitability for Applications

The three stud welding processes differ in their characteristics and suitability for various applications. The CD process is designed for thin gauge materials, offers low-cost equipment and studs, and produces clean welds without the need for finishing. The DA process provides strong penetrative welds, tolerates surface imperfections, and is suitable for welding large diameters. It requires ferrules to shape the molten metal. The SC process offers deeper weld penetration than CD, is suitable for hot rolled/coated materials, and is more tolerant of uneven or dirty surfaces. It can be easily automated and can utilise low-cost CD studs. Ferrules are not required, but the use of shrouding gas can improve weld spatter.

Additionally, each process has its own advantages and considerations, making them suitable for different material thicknesses, surface conditions, and welding requirements. For more information about what each stud welding process is suitable for, see our article on stud welding applications. If you are still unsure of the best process/ products for your requirements, get in touch to speak to one of our stud welding experts who can guide you based on your individual needs.