+44 (0) 1924 452123

sales@taylor-studwelding.com

AUTOMATED MACHINES

Our CNC Stud

Welding Systems

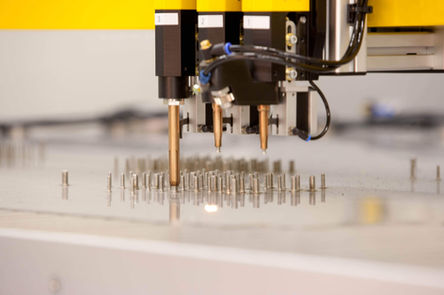

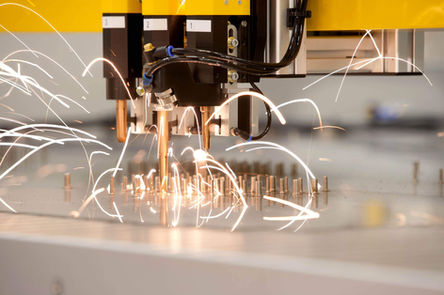

Fully automated stud welding is at your fingertips with our range of CNC stud welding machines. With our CNC machines, every aspect of the stud welding process can be computer-controlled and automated, from stud feeding and welding to loading and unloading. These machines always provide accurate positioning and powerful, lasting results. Our CNC stud welding machines boast some of the fastest welding rates in the world, achieving up to 60 studs per minute with an accuracy rate better than +/- 0.15mm. You can weld areas of up to 3000 x 2000mm with a Taylor Studwelding CNC stud welding machine, with up to 4 axes available for welding multiple studs (of 3mm to 8mm diameter), across multiple components, in a single program. Easy programming and a quick-change system make it ideal for both long and short production runs.

You can also use our CNC stud welding machines with robots as a fully automatic, 5 axis stud welding solution perfect for 3D objects. All in all, a fully automated CNC machine is a highly economic and efficient choice that offers superior versatility and reliability. These machines have been designed, manufactured, and extensively tested in the UK with the high quality and ingenuity that Taylor Studwelding always provides.

Designed and built to meet all required standards. All Taylor Studwelding CNC systems are CE and UKCA marked.

4 Axis Automatic Stud Welding Machine (1400mm x 1200mm)

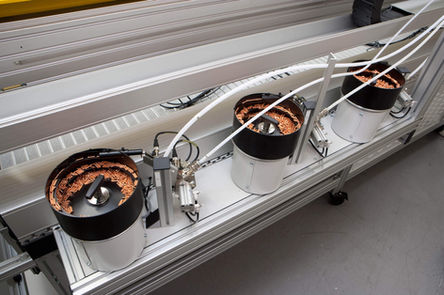

This CNC stud welding machine has 4 axis welding capabilities. It is easy to programme for long or short production runs with quick changeover functionality. PC or PLC control are both available, as well as servo or stepper motor drivers with linear encoders for high positional accuracy on servo systems. A bowl feeder unit can automatically supply threaded, unthreaded, or internally threaded studs (M3 to M8 diameter and 6mm-35mm length as standard). This machine has an accuracy of 0.15mm.

CNC Stud Welding: The Benefits

CNC Stud Welding Machines Features

-

Fast and highly economic method of stud welding.

-

Easy programming and quick change facilities.

-

Ideal for both long and short production runs.

-

Welding rates of up to 60 studs/minute maximum.

-

Manufactured to meet specific production line requirements.

-

Level of accuracy better than +/- 0.15mm.

-

Welds many components simultaneously.

-

Can be programmed off-line from any suitable computer system.

-

Available with component delivery and exit systems.

-

Multiple controllers increase weld speeds.

-

2 axis, 4 axis, and 5 axis robotic stud welding options available.

-

Weld areas of up to 3000 x 2000mm.

-

Rigid open Aluminium frame with “T” slot profile bed.

-

Fitted with linear encoders to give high positional accuracy (Servo systems only).

-

Fully guarded with automatic doors, light guards and soundproofing.

-

Available with either PC or PLC control and heavy-duty Servo or Stepper motors.

-

Systems will weld threaded, unthreaded and internally threaded studs in Mild Steel, Stainless Steel, Aluminium Alloy and Brass from M3 to M8 diameter and 6mm to 35mm length as standard. Other diameters and lengths available upon request.

Ready to start using a CNC stud welding system or have questions about our machines? Get in touch with Taylor Studwelding today and we will be happy to discuss your requirements.

SPEAK TO A STUD WELDING EXPERT

Contact Us

Fill in the form below and a member of our team will be in touch.

DO YOU HAVE AN ENQUIRY?

Get In Touch

Our knowledgeable staff are here to provide you with in-depth technical information and advice on our wide range of stud welders and stud weld equipment. You can get in touch with us and find our international contact details on our contact page or fill out a quick form and one of our stud welding specialists will get back in touch with you!